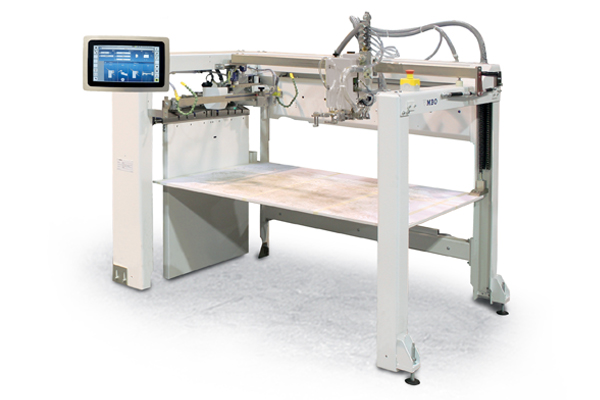

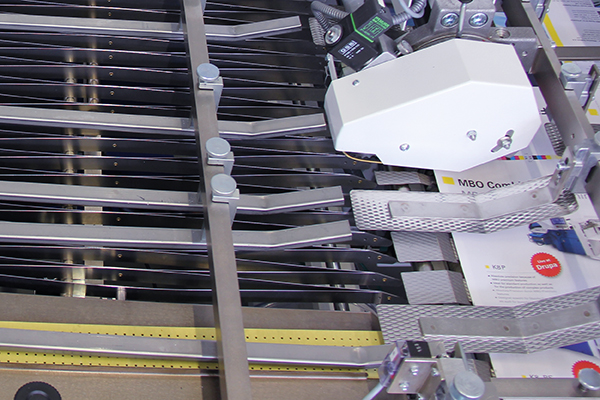

In their portfolio, MBO and H+H have various feeders to suit your individual production requirements and the available space. But no matter which feeder you choose – we guarantee reliable and precise guidance of the paper into your folding machine.

Feeders from MBO and H+H

Feeder types

Feeder heads

Sheet infeed and sheet alignment systems

Environmentally-friendly and efficiency-enhancing advancement ot the MBO palletized feeder

MBO used the Alliance Days 2021 in Solms to present the latest developments in the field of palletized feeders. The research and development department at MBO wanted to develop a more efficient, environmentally-friendly solution that also works even more effectively. According to R&D Manager Sebastian König, they did just this: “The innovations affect several areas of the feeder. Among other things, we have revised the air flow, which is now much more efficient. We also use a regulated pump that only runs when needed. This saves valuable energy”.New Vacujet / Vacujet RS feeder head

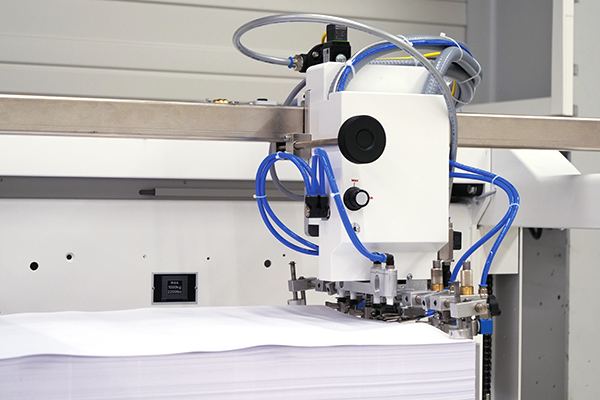

The newly developed Vacujet / Vacujet RS feeder head, a logical advancement of the Vaculift / Vaculift RS, which has been very successful on the market for many years, scores points with improved, ergonomic ease of operation. It significantly boosts efficiency and productivity. The Vacujet feeder head achieves up to 22,000 cycles per hour depending on the paper; with the Vacujet RS feeder head, up to 25,000 cycles per hour are possible. The range of applications of the new feeder head clearly stands out from the systems found on the market up to now.

Improved air flow in the palletised feeder

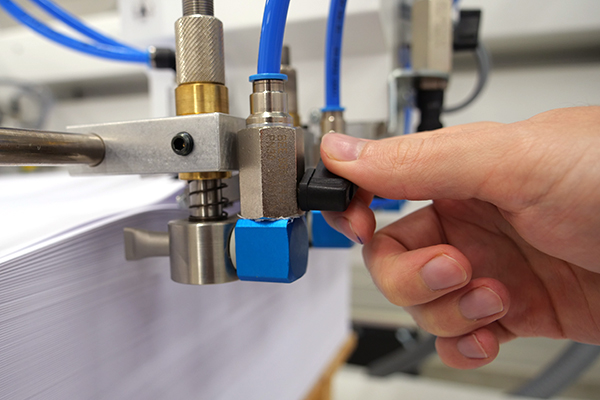

The Vacujet RS includes a revision of the palletized feeder. It now features improved air flow, which means increased productivity. The lifting unit has been equipped with a pneumatic cylinder, which increases its durability. The adjusting elements have also been moved further down, which simplifies adjustment and operation of the feeder for smaller people.

Environmentally-friendly, high-performance pressure-vacuum pump

The palletized feeder is also optionally equipped with a new high-performance pressure-vacuum pump which no longer regulates the air supply continuously, but adapts individually to the process and regulates it according to the exact needs. This energetically very efficient and thus environmentally friendly solution uses 50% less energy than conventional pumps on the market. The new pump is also equipped with a ventilated noise damping device which considerably reduces noise emissions.

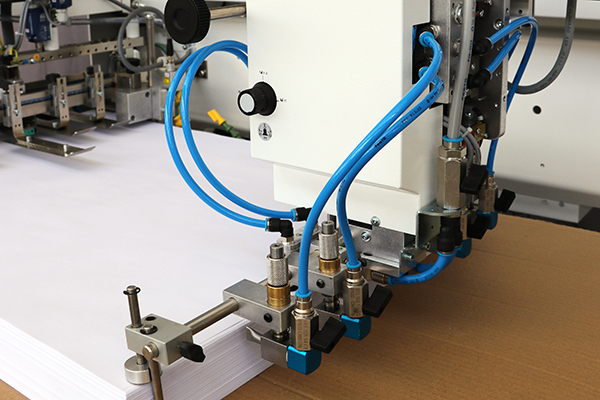

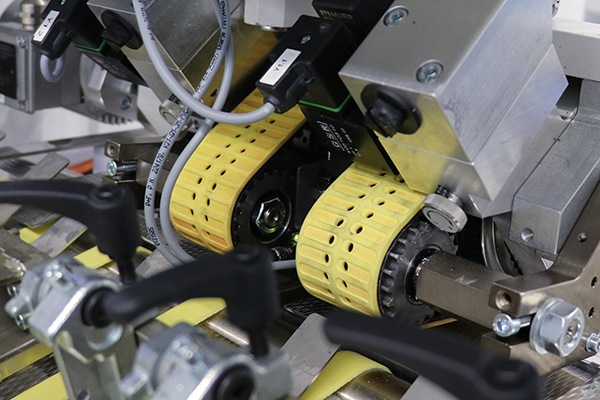

Increased suction power during sheet infeed

The Vivas system from MBO has been ensuring reliable flat sheet infeed and optimum sheet running with high throughput capacity for years. Vivas also guarantees that there are no marks, even with delicate and freshly printed products. The double vacubelt for the sheet infeed has been modified and now has four valves with increased suction power. This allows a further increase in overall performance.

Conversion option for existing folding machines

Those who would like to benefit from the new developments do not necessarily have to invest in a new folding machine. A number of folding machines with palletized feeders can be converted. Each folding machine must be checked individually to determine if this is possible. Interested parties are requested to contact their responsible MBO dealer or contact the MBO customer centre directly.

read more

read less

Vacujet / Vacujet RS feeder head conversion

The newly developed Vacujet / Vacujet RS feeder head, a consistent further development of the Vaculift /Vaculift RS, which has been very successfully established for many years, scores points with improved, ergonomic ease of operation. It significantly boosts efficiency and productivity. And its range of applications raises it a clear cut above the existing systems in the market.Vacujet

Depending on the paper, the Vacujet achieves a rate of up to 22,000 cycles per hour.

Vacujet RS

Depending on the paper, the Vacujet RS achieves a rate of up to 25,000 cycles per hour. It can also be optionally equipped with a new high-performance pressure-vacuum pump which regulates the air supply not continuously, but adjusted individually to the process and precisely as required. The energy consumption of this extremely energy-efficient and thus environmentally friendly solution is less than 50 % of that of conventional pumps on the market. The new pump is also equipped with a ventilated noise damping device which considerably reduces noise emissions. The Double Vacubelt of the Vivas system for the sheet infeed has also been modified and now has four valves with increased suction capacity. This allows a further increase in overall performance.

Conversion

Please contact the MBO customer center to profit from the advantages of the new Vacujet / Vacujet RS feeder head and the further options (pump, Vacubelt) for your folding machine.

read more

read less

Vacustar feeder head conversion

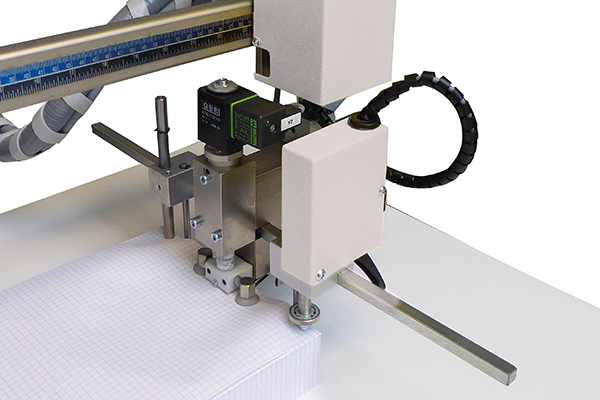

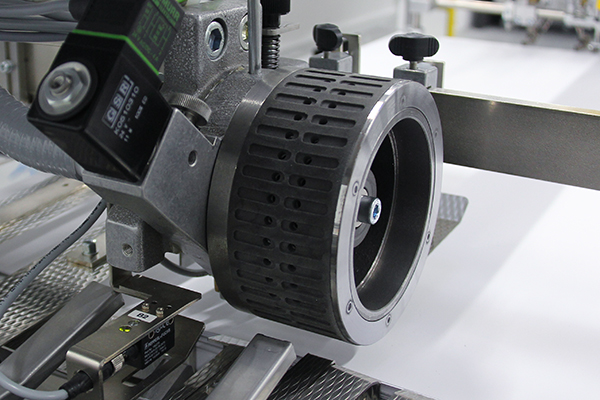

More precision for your pile feederMBO has advanced the Vacustar feeder head to simplify the transfer of heavy paper (large sheet formats, high grammages) from the pile feeder to the folding machine.

The paper suction systems are now operated by vacuum alone. This makes control of the sheet infeed much more accurate, and the sheets can also be separated more precisely. The number of wear and tear parts can also be reduced thanks to the simplified design.

New in the Vacustar feeder head

- Improved feeding behaviour with heavy paper

- Self-controlling system with vacuum-operated spring suction cups instead of electrically switching parts

- Finer adjustment options at the sheet infeed

Your advantages

- Precise separation of heavy sheets

- Up to 60,000 cycles an hour

- Fewer wear and tear parts

- Easy operability

- Automatic height adjustment at the rear of the stack

The feeder head conversion "Vacustar" is suited for the T500, T520, T530, T535 buckle fold machines as well as the K530 and K760 combi folding machines, subject to an advance test. Other buckle fold and combi folding machine models on request.

Conversion

If you are interested, please contact the MBO customer center.

read more

read less

Image gallery

Contact

Sales

If you frequently have several signatures on a pallet, the MBO Autopilot might be of interest to you. It prevents mixing of the folded signatures. Click here for further information:

Autopilot