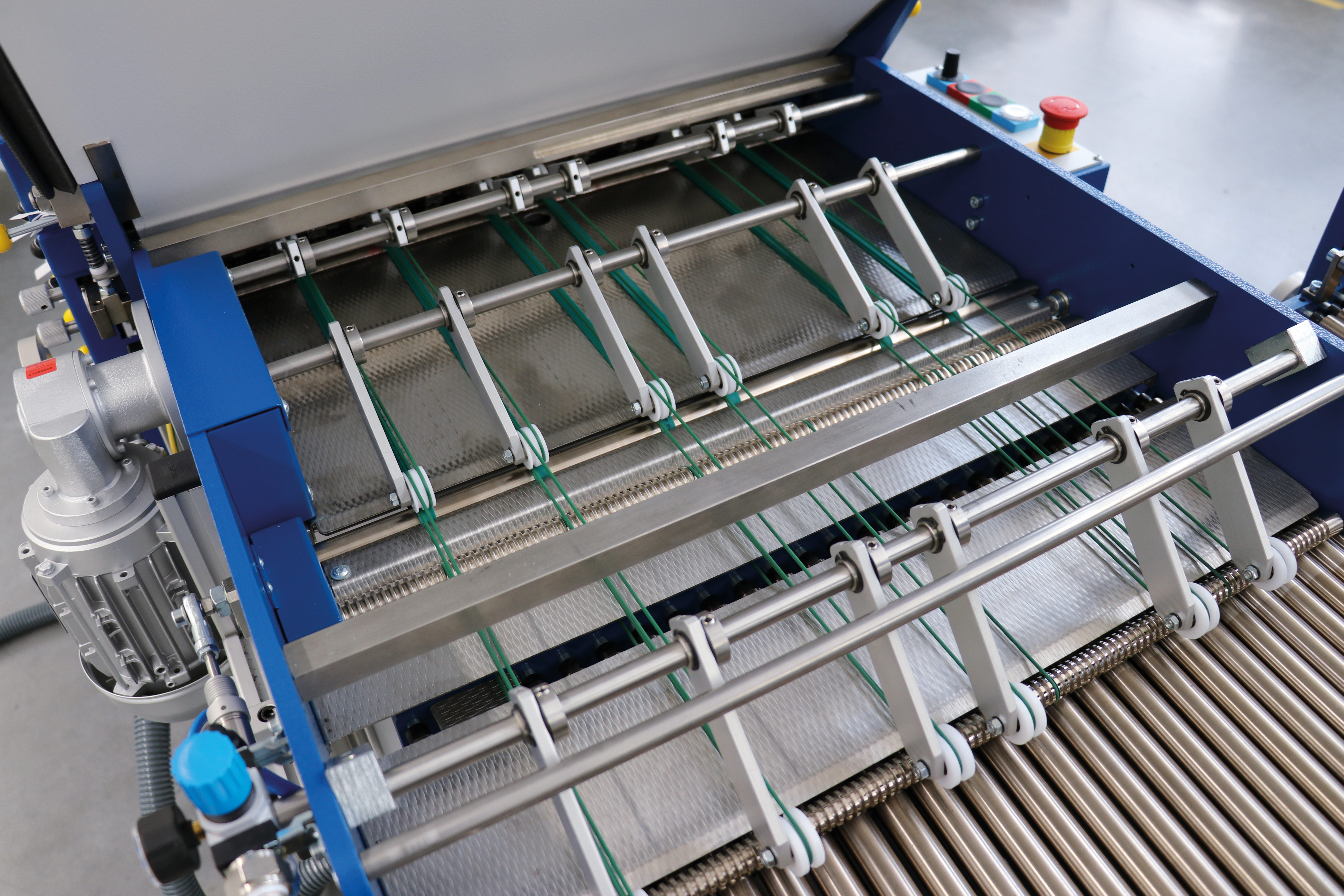

The H+H smallest folding machine KL112.1 is designed for the production of small and smallest folded products. Due to the folding roller diameter of only 26 mm, a minimum fold length of up to 18 mm can be achieved.

In conjunction with a maximum number of pockets of up to 24, large sheets can be folded down to a minimum final format.