The K70 is the entry level model from MBO. It is available as a manual machine and has an extremely good price / performance ratio. The K70 is suitable for high-precision, high performance production of folded products such as signatures and flyers in medium and high print run lengths. Even complicated folding impositions can be produced with absolute precision.

MBO K70

Features

Standard features

-

M1 Basic machine control with touchscreen

-

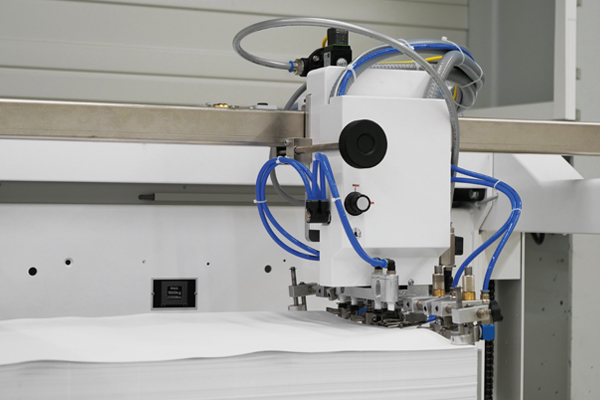

Feeder head Vacustar in the pile feeder

-

Feeder head Vacujet in the palletized feeder

-

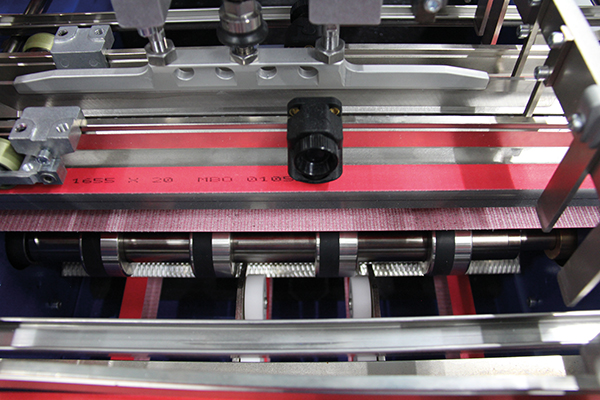

Buckle plates with swing deflector

-

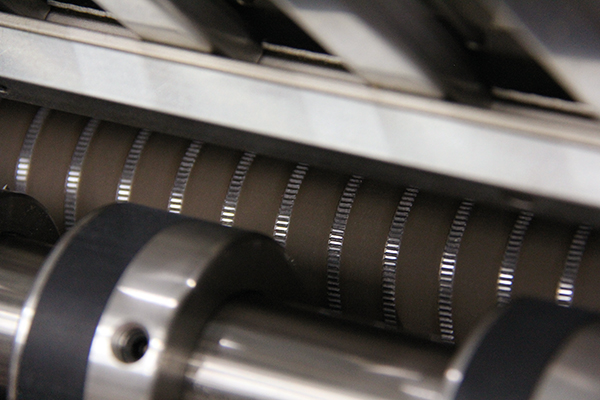

Spiral fold rollers with hard PU in the parallel fold

-

Variable output sensor for sheet monitoring and determination of net production

Optional features

-

Vivas (Vacubelt and Vacutable)

-

Combination buckle plates

-

Gatefold plate

-

Slitter shafts in the three-fold

-

RAS Remote Access Software

-

Datamanager 4.0 (only available in conjunction with RAS Remote Access Software)

Features in detail

More information

Contact

Sales

You are interested in our deliveries? Get further information here:

Deliveries