The K8 combi folding machine stands for absolute precision and exemplary productivity. As a high-performance machine, it is designed for exceptionally high production speeds and production stability with minimum set-up times. With the K8, high performance, quality and flexibility go hand in hand, resulting in a folding machine which is ideal both for standard production runs and the creation of demanding and complex products.

MBO K8

As standard, the K8 comes with numerous high-end features, offering not only efficiency but also outstanding convenience of operation. For example, the intuitive M1 Advanced control and waste paper ejection through the cross fold sheet stop. Further configuration options, for example with regard to the range of folding types and level of automation, allow optimum adjustment of the machine to the production environment.

Features

Standard features

Machine control

- Machine control M1 Advanced with touchscreen

- RAS Remote Access Software

Feeder

- Continuous feeder

- Vivas (Vacubelt and Vacutable)

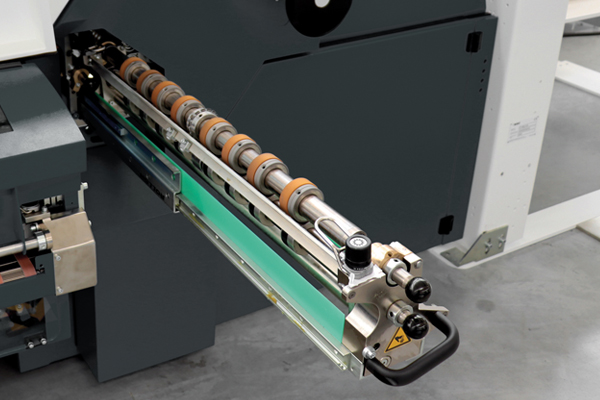

Parallel fold

- 4 buckle plates

- 1st buckle plate with swing deflector and continuous sheet stop

- 2nd-4th buckle plate with swing deflector

- Virotec fold rollers

- Slitter shaft cassette for single rear slitter shafts

- Perforating-, scoring- and cutting devices for standard jobs

- Maintenance and noise-free belt drive

- Noise damping and safety device

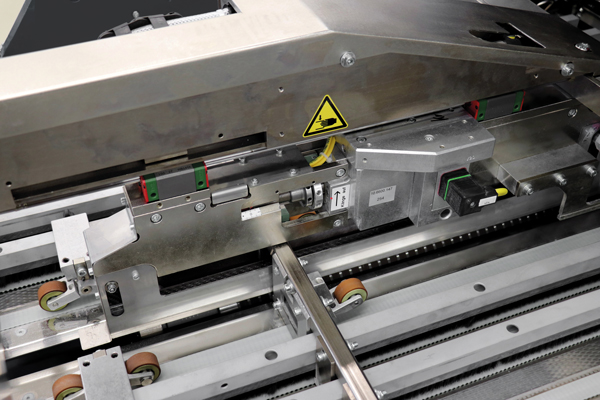

Cross fold / three fold

- Vacuknife cross fold knife with adjustable length

- Super-KTL configuration

- 1 buckle plate with swing deflector

- Vacuknife three fold knife

- Spiral fold rollers with hard PU

- Slitter shafts in the cross fold and three fold

- Swing-up cross fold knife area

- Slide-out three fold knife area

- Cross fold sheet stop for ejection of waste paper, including ultrasonic double sheet control

- Perforating-, scoring- and cutting devices for standard jobs

- Maintenance and noise-free belt drive

Optional features

Machine control

Additional feature

- Datamanager 4.0 (only available in conjunction with RAS Remote Access Software)

Feeder

Alternative feature

- Palletized feeder with feeder head Vaculift RS or feeder head Vacujet

Parallel fold

Alternative features

- 6 buckle plates

- 2nd-4th (optionally up to 6th) buckle plate as combination buckle plates

Additonal features

- Gatefold plate

- Various slitter shaft accessories, for example gully cut device, edge trim device, punch perforating device, multiple perforation device, etc.

- Glue fold device

Cross fold / three fold

Alternative features

- Super-KTLT configuration

- Super-KTZ configuration

- 1 combination buckle plate (with Super-KTLT configuration up to 2 combination buckle plates)

- Virotec fold rollers

Additional features

- Various slitter shaft accessories, for example gully cut device, edge trim device, punch perforating device, multiple perforation device, etc.

Optional automation

- Buckle plates, sheet deflectors and fold rollers in all folding units

- Slitter shaft settings in the cross fold / three-fold

- Cross fold knife length adjustment and sheet stop adjustments in the cross fold / three-fold

Features in detail

More information

Contact

Sales

The K8 is significantly upgraded with the CoBo-Stack collaborative stacking robot. Get further information here:

CoBo-Stack