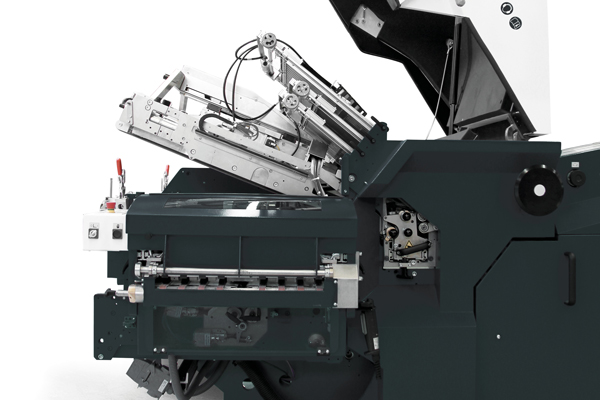

The fastest folding machine in the world

The K8RS is the frontrunner among the MBO combi folding machines. Based on the high-performance K8, the K8RS is trimmed for peak productivity. In addition, it features valuable, performance-optimising enhancements which not only allow the outstanding production speed of the folding machine but also guarantee the highest production quality and stability.