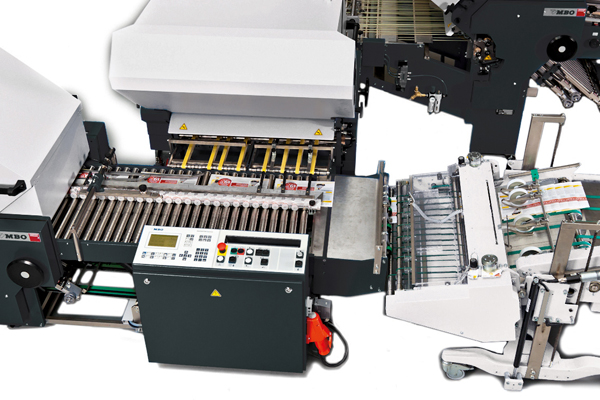

MBO folding machines and features are orientated on the users – both regarding practical requirements and the variety of the paper medium. Convenience plays a major role. The simpler the processes and workflows, the more efficient becomes production. With its high performance and excellent quality, the T1420 provides the ideal preconditions for highest productivity. A broad range of folding types and individual automation options guarantee that the Perfection models live up to their names.

MBO T1420

The equipment features of our folding machines have been especially designed for the purpose of their application. We never rest on our well-proven product development achievements but always try to recognise new requirements as early as possible. Ideally soon enough to offer you a solution before you even face the problem. Some of these special solutions can be found on the T1420.

Benefits of the T1420

- Unique MBO features make the handling of large formats easier and faster, allowing the machine to be operated by one person only

- Double stream, RFE and automation allow shorter set-up times and a more efficient production, thus making you considerably more productive and competitive when working with the T1420

Features

Standard features

-

MABEG palletised feeder M 6/1650

-

Airstream double alignment table

-

Sheet alignment by Vacutable

-

4 Multiplate buckle plates with swing deflectors (folding unit I)

-

Combiplate combination buckle plates

-

Low maintenance and low noise belt drive

-

Ring fold rollers with soft PU roller coating (folding unit I)

-

Scoring, perforating and cutting devices for standard operations

-

Slitter shaft cassette for single rear slitter shafts with plug bearings

-

Transfer table with double sheet and misfolded sheet ejection

-

High-Speed-Guide

Optional features

- Datamanager

- MABEG palletised feeder M 6/2050

- Slitter shaft cassette (folding unit II and III)

- Noise insulation unit

- Spiral fold rollers

- Strip cutting device, special and edge trimming device, multiple perforation unit, punch perforation unit

- Divided hard metal slitters (punching and V perforation), emptying and recharging of the slitter shafts no longer required

- Double stream unit with upwards folding conveyor table

- Three-directional stream unit (folding unit II)

- Sheet return unit RFE (folding unit III)

- Pre-slitter shafts (folding unit II)

- Automation options

Features in detail

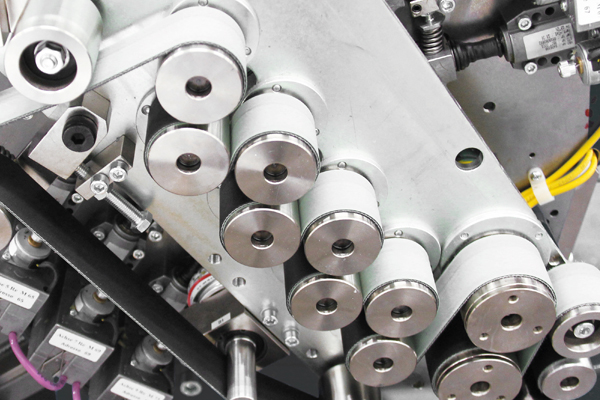

Feature Multiplate buckle plates

All setting elements like the folding length, position and pretensioning of the lower plate lip, inner width and clamping of the buckle plates are installed on the operator side, thus ensuring both ergonomic and efficient handling for the operator. In order to be able to quickly and comfortably swing the deflectors, the T1420 equipped with pneumatic cylinders which automatically regulate the retraction and extension movements. Therefore, “winding out“ the buckle folds is a thing of the past. The through sheet stop ensures that the sheet lies exactly against the stop and is not deformed.read more

read less

Contact

Sales

Retrofit

We inform users of MBO buckle folders with MS/MC control, series T460/B118, T530/B21, T535E, B21-IFF, B26E, B30E/B30A and T700P-T1420P that a modification kit which includes an update of the safety status is available. For further information, please contact: +49 (0) 7191 / 46-503 or milica.damcevska@mbo-pps.com.

You are interested in our deliveries? Get further information here:

Deliveries